Founded in 1919, Fairfield™ Manufacturing possesses a century of experience building custom gears and drive systems.

Global Original Equipment Manufacturers rely on Fairfield™ for fully integrated gear production capabilities delivering superior performance across a wide range of industrial and mobile applications. Whether you need a contract manufacturer that can build precisely to your print or a motion technology expert capable of solving your most complex gear performance issues, you can rely on Fairfield™.

What does FAIRFIELD™ stand for?

Fairfield™ retains a leading position within the gear industry as a company we are one of the largest producers in North America. From our manufacturing location in Lafayette, Indiana, USA, and complemented with a satellite facility located in Belgaum, India, Fairfield™ serves a customer base worldwide.

With our specific know-how and engineering expertise, we are a global solutions provider for gears and drive systems for on- and offshore applications.

The manufacturing location in North America

Certified by some of the world’s most prestigious authorities for a variety of manufacturing processes, Fairfield™ is a benchmark in its industry and further consolidates the values and principles of quality, performance and sustainability.

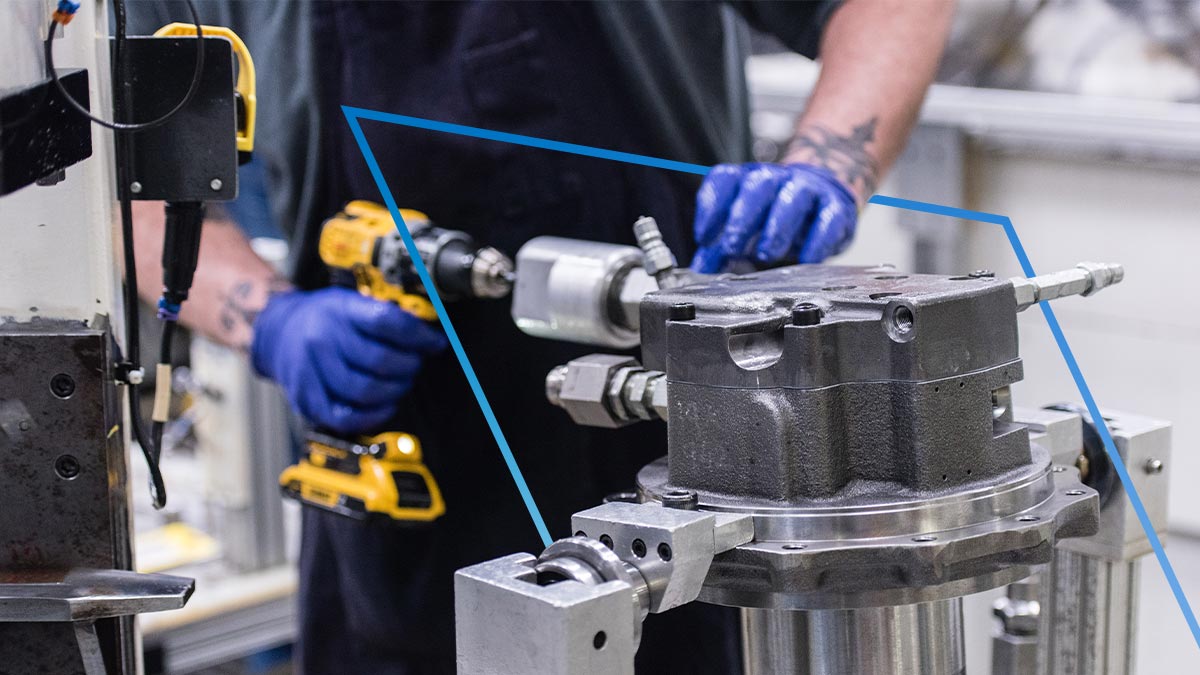

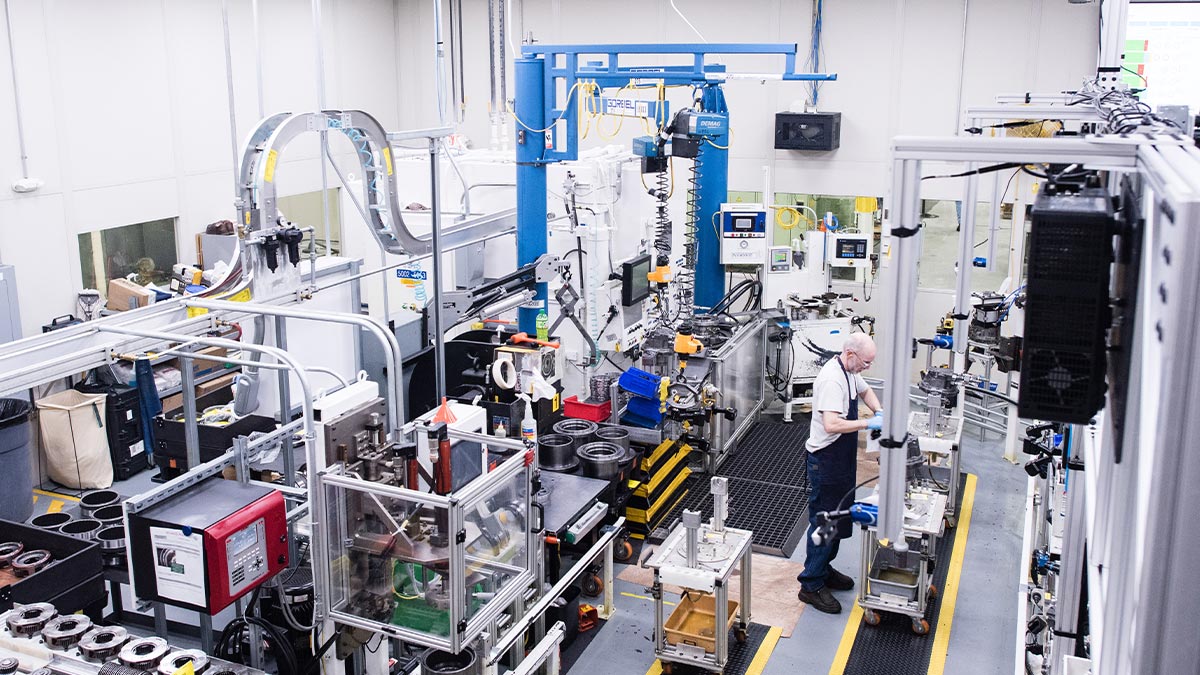

Fairfield™ enhances production capabilities and equipment

To engage the rapidly increasing interest in compact track loaders (CTLs) and other small- to mid-sized construction vehicles in North America, our facility in Lafayette is enhancing its process capabilities and equipment.

By doing so, we nearly tripled our annual production of Spicer Torque-Hub track drives within the current footprint of its manufacturing and assembly hub in Lafayette. The expansion includes installing automated assembly processes managed by a full manufacturing execution system, extending already robust lean manufacturing initiatives, and incorporating next-generation quality controls.

Quality and Certifications

Fairfield™ has unique capabilities to machine and heat treat large components. We maintain certifications with the American Bureau of Shipping, Lloyds Register, the Association of American Railroads, the Performance Review Institute’s Transportation and Power Generation Program, and DNV. Our certifications cover various aspects of our business including non-destructive testing, heat treating, the manufacture of bull gears, pinions, and starter gears, ISO 9001:2015 and IATF 1649:2016 registrations, and quality assurance and type approvals for marine jacking systems.

Discover other areas

The markets we cover

Our team is dedicated to delivering excellence from the initial solution assessment through ongoing service for the entire lifespan of your application.

Discover more

The capabilities we provide

We engineer, manufacture, test, certify, and supply precision-made Fairfield gears and gear drives for an expansive range of industrial and mobile applications.

Discover more

Contact

For more information on our products and services or to discuss your specific gear performance requirements, please do not hesitate to contact us. Our team of dedicated experts is here to assist you in every step of the way, ensuring that your vision is brought to life with superior quality and performance.

Contact us